The mathematical model that optimises production

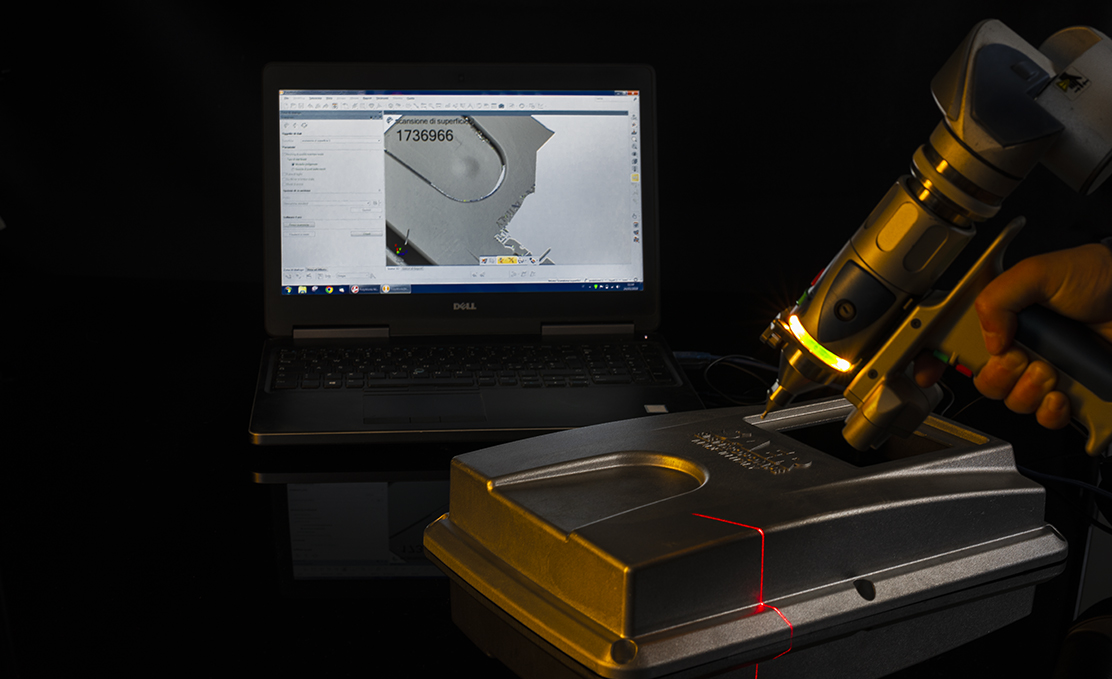

The reverse engineering service of die-casting moulds is useful for all customers that wish to extrapolate the data of a project starting from the existing product. The object is scanned and measured by tools capable of transforming it into a 3D CAD model. Through the use of lasers, touch probes and photogrammetry, it is possible to obtain the information to replicate the mould for the die-casting of aluminium, zamak and brass that needs to be produced. If the mould is old and has no 3D files or technical data that allow it to be reproduced, then FPM offers the reverse engineering service of the die-casting mould to obtain a solid mathematical model that can be replicated and reused both for 3D printing and the actual production of the mould.