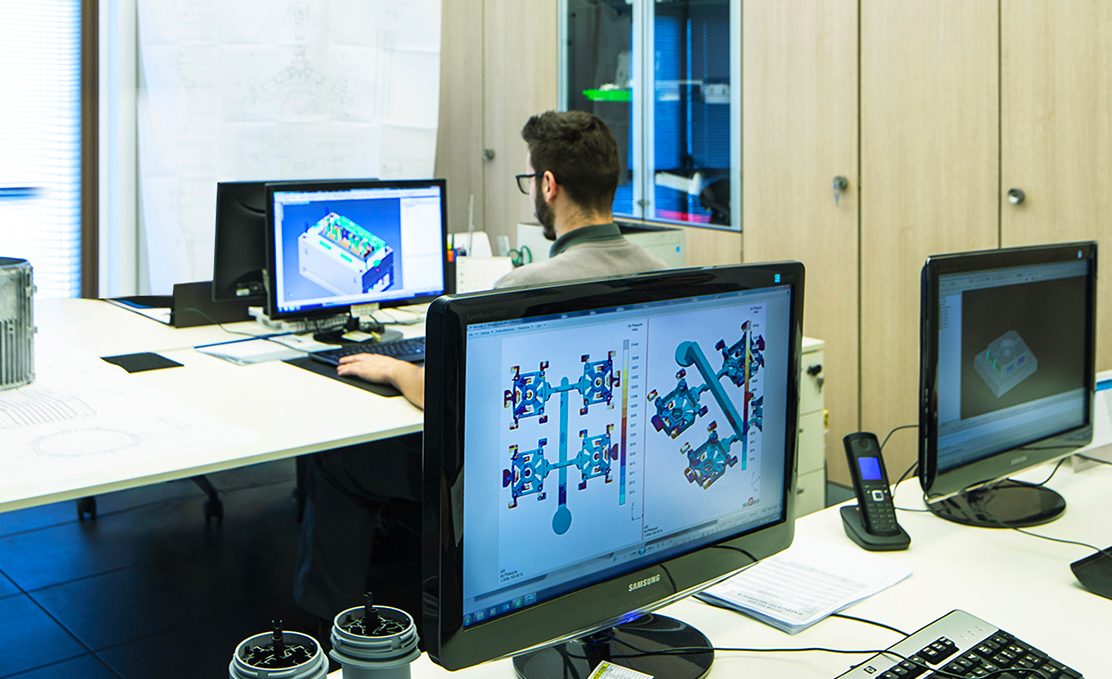

Analysis and evaluation that optimise production

The feasibility study for thermoplastic moulds proposed by FPM is the first fundamental link in the production chain. It is important because it prevents problems during and after mould production. For example, the feasibility study means it is possible to foresee draft angles for an optimal extraction of the piece from the mould. A first approach to the project that includes a feasibility study for thermoplastic moulds allows the preventive evaluation of the values of weight, pressure, cooling times, and many other variables. Always starting from the customer’s needs, the feasibility study helps to optimise the moulding process.