From mould to project: all the useful parameters

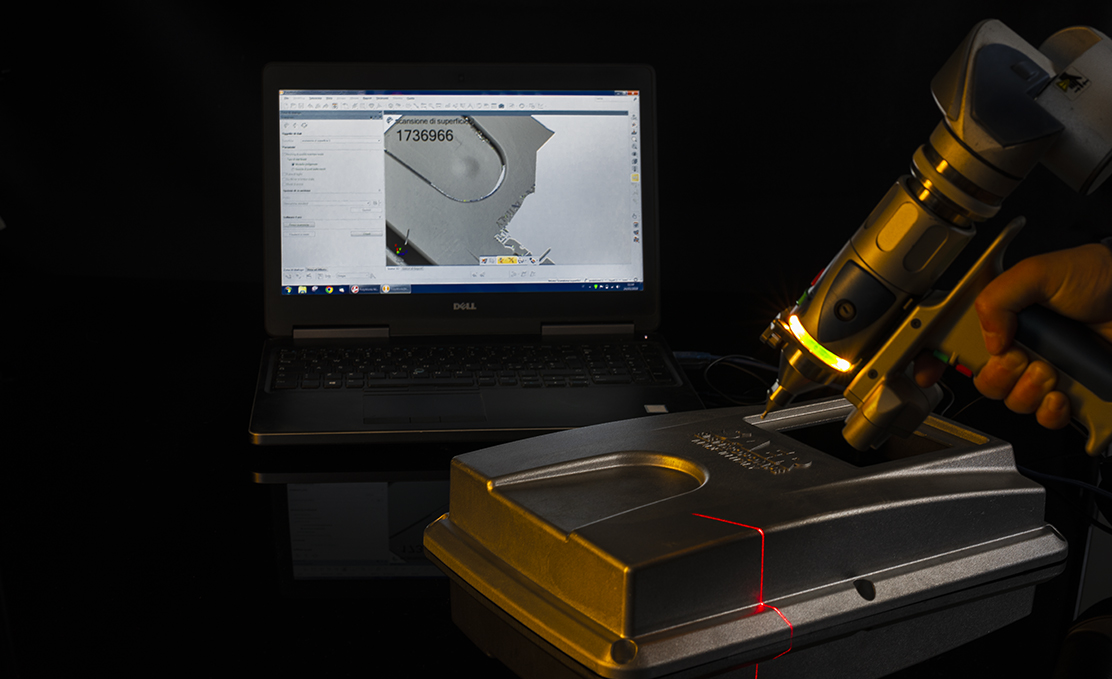

A plastic injection mould does not always come with a complete project that shows the data useful for its reproduction. When such a situation arises, for example because the mould is very old or because this information has been lost, FPM provides the reverse engineering service for thermoplastic moulds. Thanks to 3D scanning and measurement techniques with lasers, touch probes and photogrammetry, it is possible to obtain a solid mathematical model. Such data collected with the reverse engineering of the mould form the parameters required for the reproduction of the object.

The reverse engineering service for thermoplastic moulds is useful for all customers that wish to extrapolate the data of a project starting from the existing product or object. The object is scanned and measured by tools capable of transforming it into a 3D CAD model.Through the use of lasers, touch probes and photogrammetry it is possible to obtain the information to replicate the thermoplastic mould.