The process that reduces costs and production times

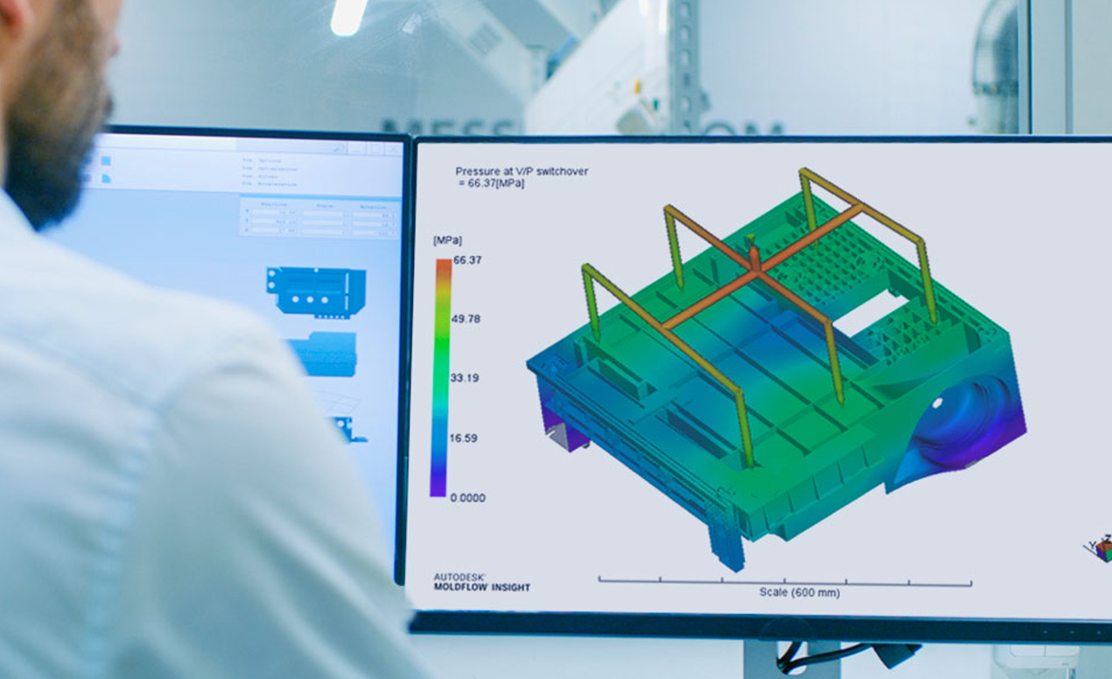

The simulation tools for plastic injection moulding allow the reduction of costs and time-to market because they provide a complete and high-performance vision of the whole moulding process, before it actually starts. Thanks to FPM’s dedicated software for the simulation of thermoplastic injection it is possible to tackle problems that may occur during the production phase, such as the presence of bubbles or pockets of gas in the cast, which affect the quality of the moulded component. The filling simulation is therefore the most efficient way to obtain truly high-performance moulds.